Collaborative tools for rig teams help complex assets

Various software development efforts have been initiated to boost the revenues of the energy sector in the USA. Successful technical advances have resulted in the creation of a series of customized packages for onshore operations and offshore processes in the oil and gas industry. They have been able to address numerous challenges that operators often face while handling vertical, directional or horizontal wells – Thereby helping in prolonging the life cycle. Considering that this sector has several complex assets, each service company needs an extensive suite of special well lifecycle management software with ideal configuration. A demo may be great to showcase how a potential software works. But the real test lies in offering features and collaborative tools and also training the people to use the software.

Must-Read: Google XML Sitemap explained

Why is it essential to have collaborative tools for rig teams? Which configurations are ideal for upstream or downstream rigs? All this information is critical to streamline the ops, optimize the schedules and reduce challenges. This article stresses the drilling efficiencies and deploying ‘software in action’ rather than just presenting demos that fail at crucial junctures.

Dealing with complex assets

– Tapping integrated solutions

Generic software solutions are not enough to optimize remote rig operations nor do they have specific features that promote ideal well lifecycle management. The most critical qualities that they should be able to address include detail reports, analytics, advanced data collection, and business intelligence. All these processes are vital to optimizing schedules between the rig and remote teams. The products designed should have the functional ability to discern types of assets (for example, drilling equipment) and track the entire process through multiple locations. It should be configured for access to human resources, materials scheduling for repair work, timely maintenance and installations. This ensures that the features of the software deal with all aspects right from the conception to reclamation and if need be the abandonment of the wells that are no longer productive.

Also, read: How to get out of business debt?

That is why integrated solutions should include the following parameters to assess the well lifecycle management:

- Availability of automation and flexible workflow modules to take advantage of the active lifecycle.

- The applications should be prearranged to gather pipeline data required from each well. It will focus on in-depth analysis which is the foundation of reporting and further action.

- All information should be available for all teams involved to take action. Captured data should give real time information on the wells for optimum management.

- The report should be useful for company audits and decision making depending on the productivity of the well.

- Automation will involve communication channels like simple email formats, spreadsheets, data tracking and sharing for priority scheduling.

- The software configuration should be secure even when the lowest rung of employees is handling the OS.

- Collaborative tools need to be accessed only by admin or security personnel for the safety of all data.

- Implementation of the program works after all these points are integrated into the scheduled apps for remote teams to work seamlessly. Training the staff is equally essential rather than just providing demos as they are forgotten after the initial excitement is over.

Prepare a specific dashboard of collaborative tools

– It facilitates better coordination

For the remote teams to coordinate better, software apps need a dashboard which benefits the exercise for scheduling. Having a unique information architecture will expand the capabilities of the ops.

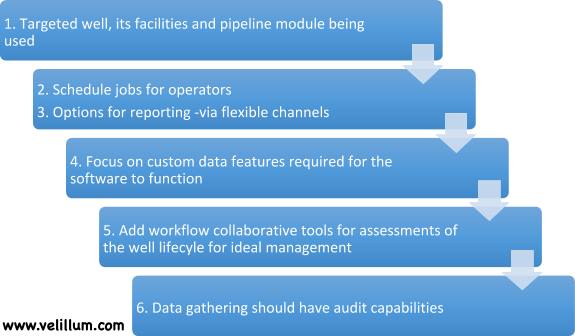

Take a look at the following 6 sharp features which employees can be trained to use.

Understand the value of planning software before coding

– Importance of training and maintenance related challenges

Any activity well organized offers a better performance strike rate. To have the performance training is essential. Properly trained staff will be able to face maintenance related challenges more efficiently and take necessary action. In the oil and gas industry, well lifecycle patterns are erratic. The energy sector constantly deals with several explorations and drilling anomalies. However, planning the right software can do wonders and reduce challenges, if not eliminate them. Giving training to the employees is an equal investment for productive growth.

Along with the ROI, the engagement of the well operators leads to better results. The customized software alone cannot guarantee the best functions of well lifecycle management unless human beings are not involved in the process and workflow. No matter how much technically advanced the software is, the trained operators benefit more rather than just depending on IT support. The biggest advantage is that they are the experts to discern when maintenance or even repair work is required. If they know this beforehand, schedules will not go haywire. Only actionable well lifecycle management software and collaborative tools can add value to the energy sector’s complicated matrix.

Think about it before investing in the management software.