Connectors are connection standards that relay information and signals between components and boards inside a more extensive system. Industrial engineers prefer the M12 due to their excellent cabling system and rugged

An M12 does not come alone. Many M12 pinouts are available for use in different electrical systems. Generally, M12 are employed to interface PLCs, factory floor’s electrical systems, and electromechanical systems.

Here, we shall know more about M12. Let’s delve right in!

M12 Connectors: What Are These?

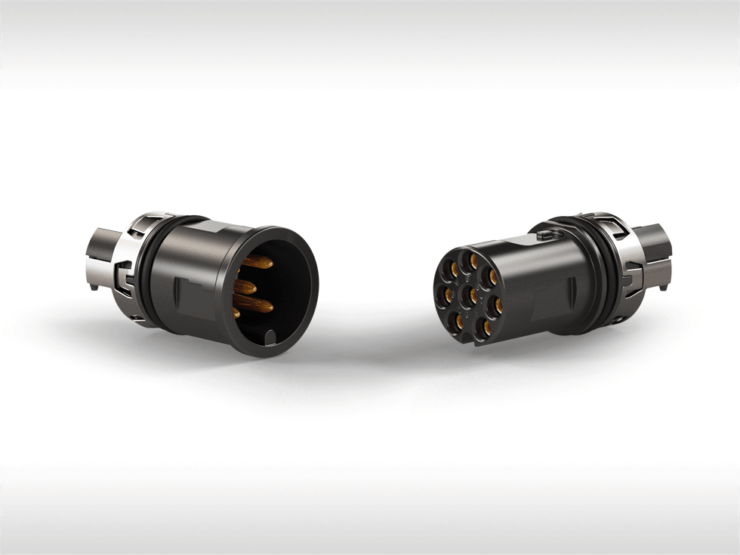

The M12 connectors, having locking threads of 12 mm, are circular keyed. If you want a flexible method for connecting your wide range of equipment, the cable offers a flexible and rugged option.

It was usually crafted for use in rusted environments, although they are also used in high-end factories to transfer high data at higher rates. Now, you might be wondering where these are used. Its primary usage is in industrial automation like industrial Ethernet, Profibus, Fieldbus, and actuators.

The M12, unlike the other like USB, are supposed to be non-removable. These are firmly linked via soldering or right-angle. They are constructed to resist environmental pressure and moisture, and they can be used for any heavy-duty work.

The shells are plated with nickel and brass or stainless steel to combat corrosion and rust. Moreover, they operate at a wide temperature range, which goes from -40oC to 85oC.

This range goes way lower than freezing to high temperatures in various factories. Once installed, the M12 flexible cast lower temperature tolerance than the others.

M12 Connector Codes

M12 codes depend on the need to relay power or data.

Data Applications

There are five major Check here types coded using the labels – A, B, C, D, or X. They have many pins varying in numbers like 2, 3, 4, 8, or 17, based on the type of signal, interface type, connector code, and the number of signals.

Remember that each of the coded operates in its own way.

Power Applications

Five M12 codes are used for DC power, AC power, and primary purposes. The S-coded ones suited for AC powers will eventually take over the C-coded M12 power parts. The sequence will go on for power application.

Pinout

It comes down to the pin numbers. The differently coded have different pinouts. For instance, a B-coded M12 might have 5 pins, C-coded might have 5 pins, and a D-coded one might have 4 pins.

TURCK M12 connectors coding

They are accessible with 3, 4, 5, 8 and 12 pins. While higher pin counts are not arranged, other locking styles, for example, knife and push-pull are consistently being worked on.

The M12 family can be found in numerous applications like plant mechanization, estimation and control, correspondences, food and drink, transportation, farming, advanced mechanics and elective energy.

With regards to explicit applications, clients should choose the right pin count. For sensors and force applications, 3 and 4 pins are required. Profinet and Ethernet utilize 4 and 8 pin counts. What’s more, Fieldbus, CANbus and DeviceNet essentially utilize 4 and 5 pin counts. At long last, indicate 12 pins for signal prerequisites.

A few styles of coding exist in M12 . This coding forestalls erroneous mating on items. Moreover, safeguarding is accessible in most coded M12. For instance, X-coded are explicitly safeguarded by the plan of their coding.

The most well-known sorts of coding include:

- A-coded for sensors, dc force and 1 Gbit Ethernet

- B-coded for Profibus

- C-coded for ac power

- D-coded for 100 Mbit Ethernet

- X-coded for 10 Gbit Ethernet

- S-coded for ac power (will ultimately supplant C-coded power parts)

- T-coded for dc power (will ultimately supplant A-coded power parts)

A-, B-, D-and X-coded are generally common. This is on the grounds that the A-, B-and D-codes have been around for quite a while and are a portion of the first M12. X-coded are turning out to be more famous for rapid modern Ethernet and will ultimately supplant the An and D-coded parts for Ethernet applications.

Another code, K-coded, is being worked on for ac power, while a L-coded configuration will be delivered soon for Profinet dc power.

convey signs and data among sheets and parts inside a bigger framework. The M12 and the connected M12/M8 framework have become top picks among modern designers, who frequently search for tough and cabling frameworks.

M12 are normally universally useful found on many link types to help conventions like Process Field Bus (Profibus). In any case, there is no single M12; there are numerous conceivable M12 pinouts that can be utilized in various frameworks.

M12 are ordinarily used to interface between PLCs, electromechanical frameworks, and other electrical frameworks on the manufacturing plant floor. At the point when you’re planning around this framework, you’ll need a M12 connector pinout to interface with signal ports on the Rx/Tx sides of an association.

In this we will dive somewhat more profound into M12 —what they are and where they ought to be utilized.

Force Applications

There are likewise 5 extra M12 codes for AC power, DC force, and universally useful use in various conventions. These are S-coded M12 for AC power, which will ultimately supplant C-coded power parts.A-coded connectors for providing DC power.Finally, the K-coded M12 is being chipped away at for AC power, while the L-coded is used for DC power in Profinet transports. The table beneath sums up the different M12 codes and their applications.

Final Words

That’s a wrap for now. It’s essential to know how to select suitable M12. Go through the temperature ratings and absolute maximum power to ensure your equipment runs safely.

M12 are roundabout with a 12-mm locking string utilized for sensors, actuators, Fieldbus, and modern Ethernet, fundamentally in production line mechanization applications. Frequently with evaluations ofIP65, IP68, and IP69K, they are great for washdown and destructive conditions.